Ticket Accounting

Take All of Your Tickets Digital

Digitize 100% of Your Tickets

Integrates to Existing AP Systems

Eliminate Errors and Get Paid Faster

WATCH NOW

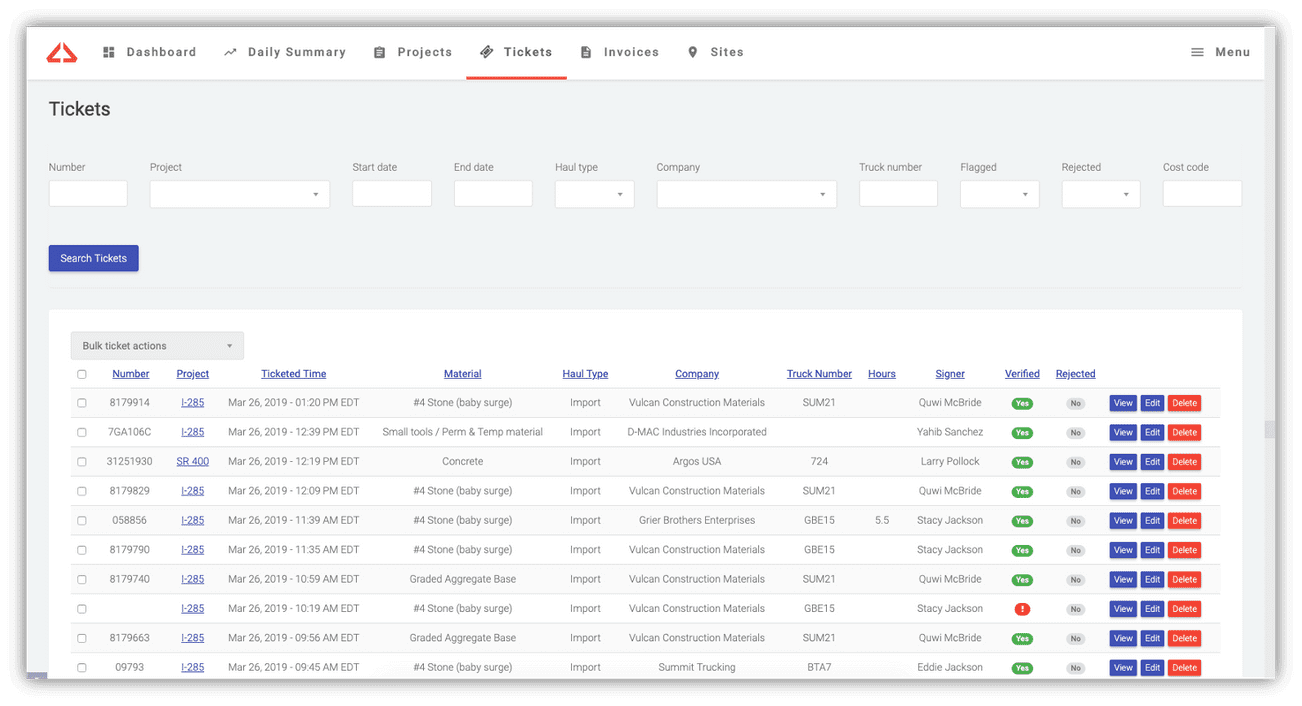

Digitize 100% of your tickets

With Command Alkon’s Ticket Accounting, tickets and invoices are digitized and stored in one location, then AI can automatically match line items from ticket to invoice – flagging the user if they are being over-billed or highlighting other exceptions requiring clarification.

“Our estimated savings are around 1.5 people. By that I mean, we would have to hire 1.5 people to do the job that Ticket Accounting does automatically,”

– IT Manager, Sunset Logistics

GET TICKETS INSTANTLY

- Electronic proof of delivery with the mobile app

- Automatically receive quarry tickets with ScaleSync

- Ticket Accounting Assist extracts ticket data and calculates hours

- Find old tickets with the click of a button

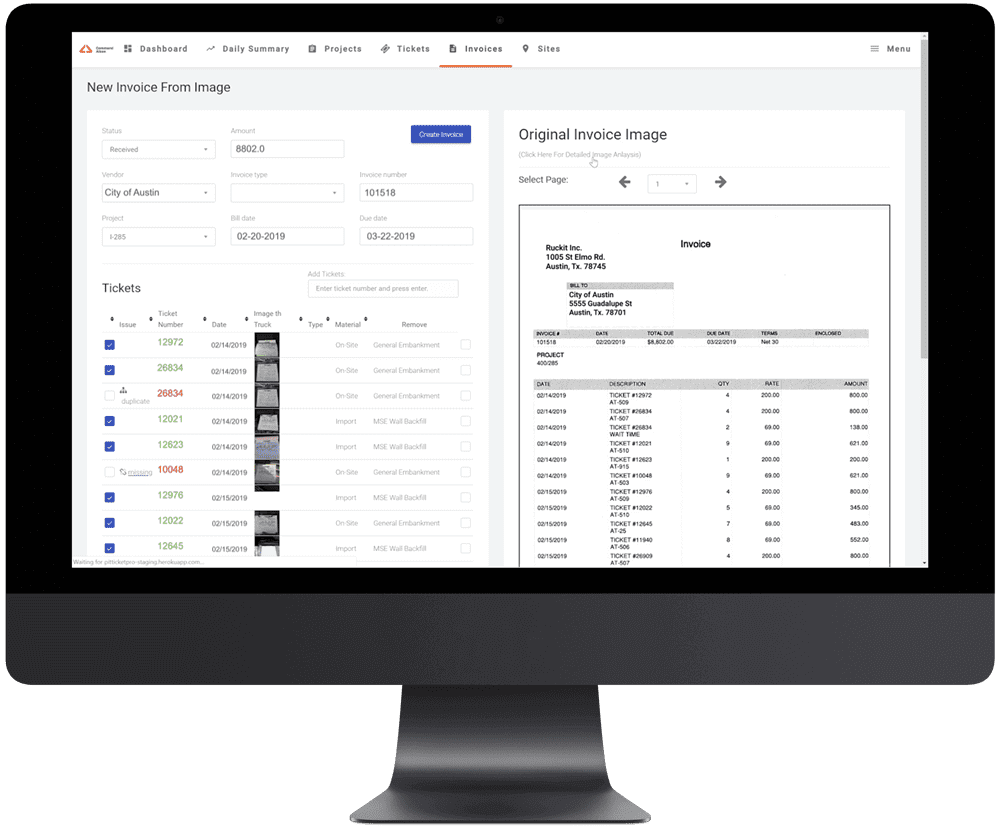

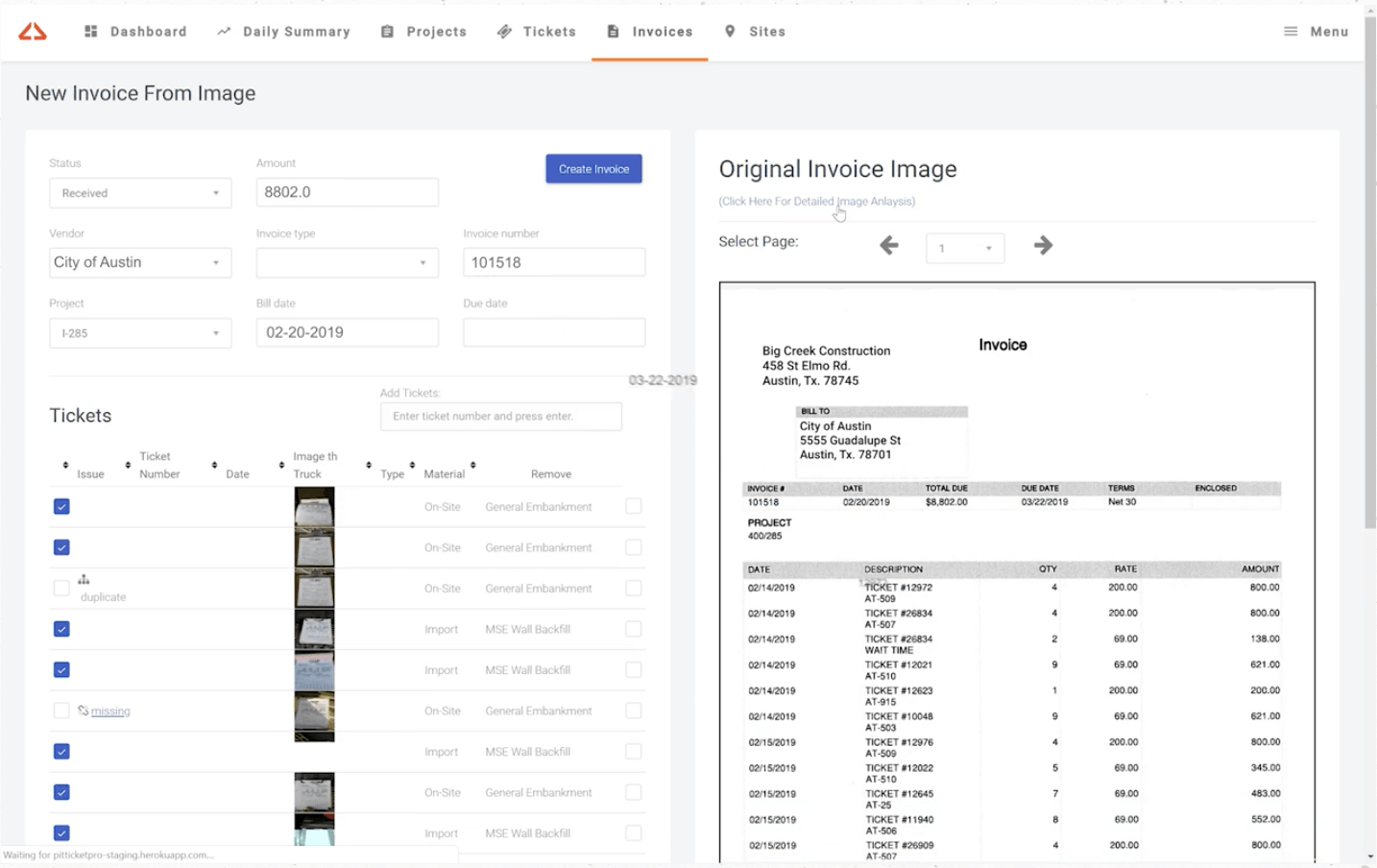

AUTOMATICALLY MATCH TICKETS TO INVOICES

- Import tickets from Dropbox, your computer, or use the scanner integration

- Automatically match invoices to tickets

- Detect missing, duplicate, and already invoiced tickets

- Searchable record of all invoices for easy auditing

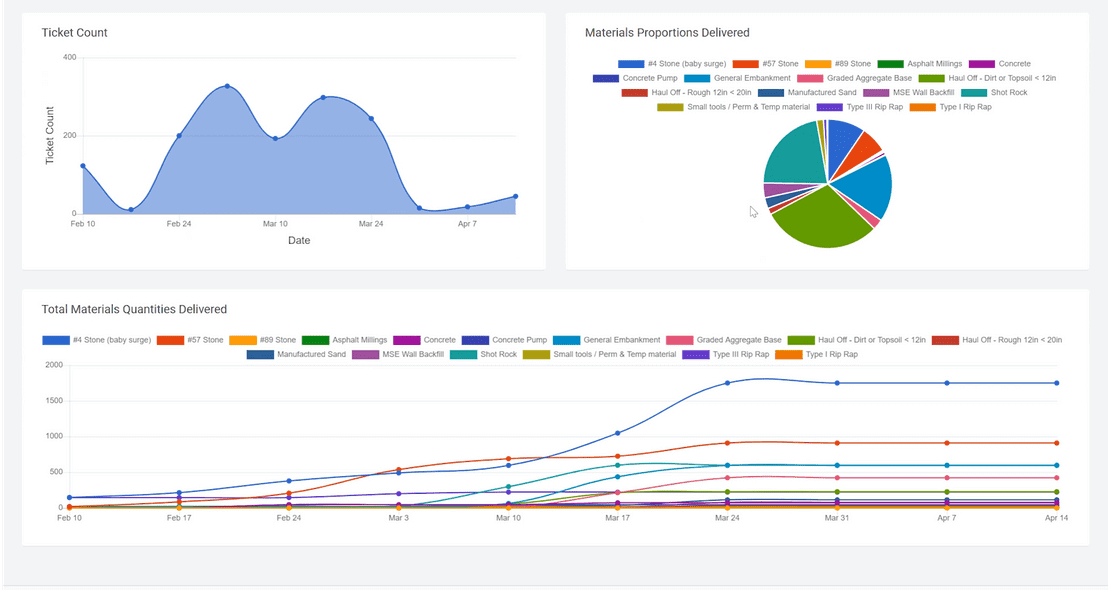

KNOW YOUR QUANTITIES AND COSTS DAILY

- Real-time quantities for each material

- Daily production summary by project, material and truck

- Automatically calculate yield for each material

- Customizable load conversion rates

- Daily materials summaries

Extend Your Value

Delivering transparency into order information to Customers from a simple mobile application

Digitize all your tickets for any inbound load at the plant, on the jobsite, and in the office

Drive decisions with critical data from anywhere with cloud-based dispatching

Request a Demo