customer portal

Order Insights Your Customers Need,

The Efficiency You Want

Reduce Routine Calls By 30%

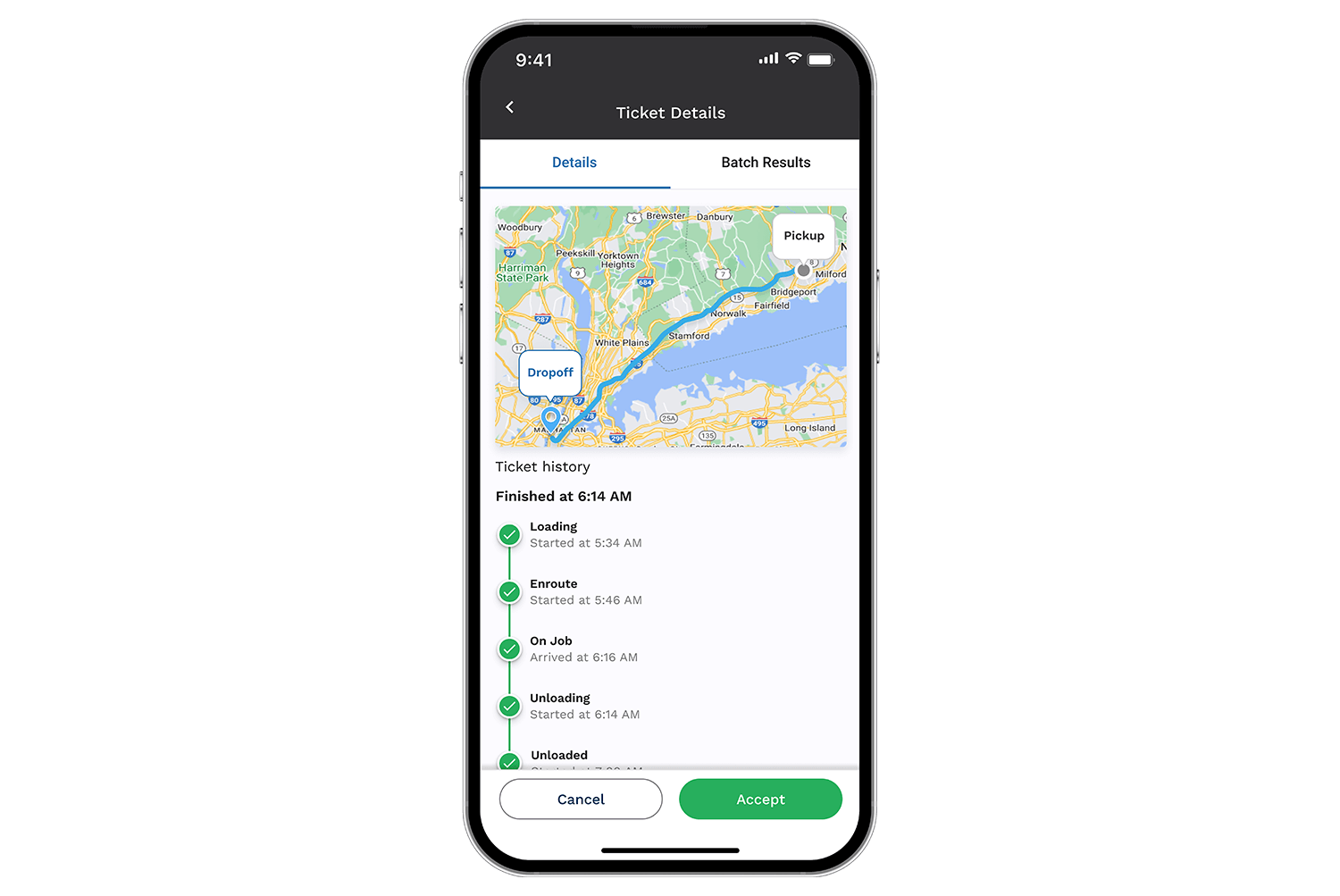

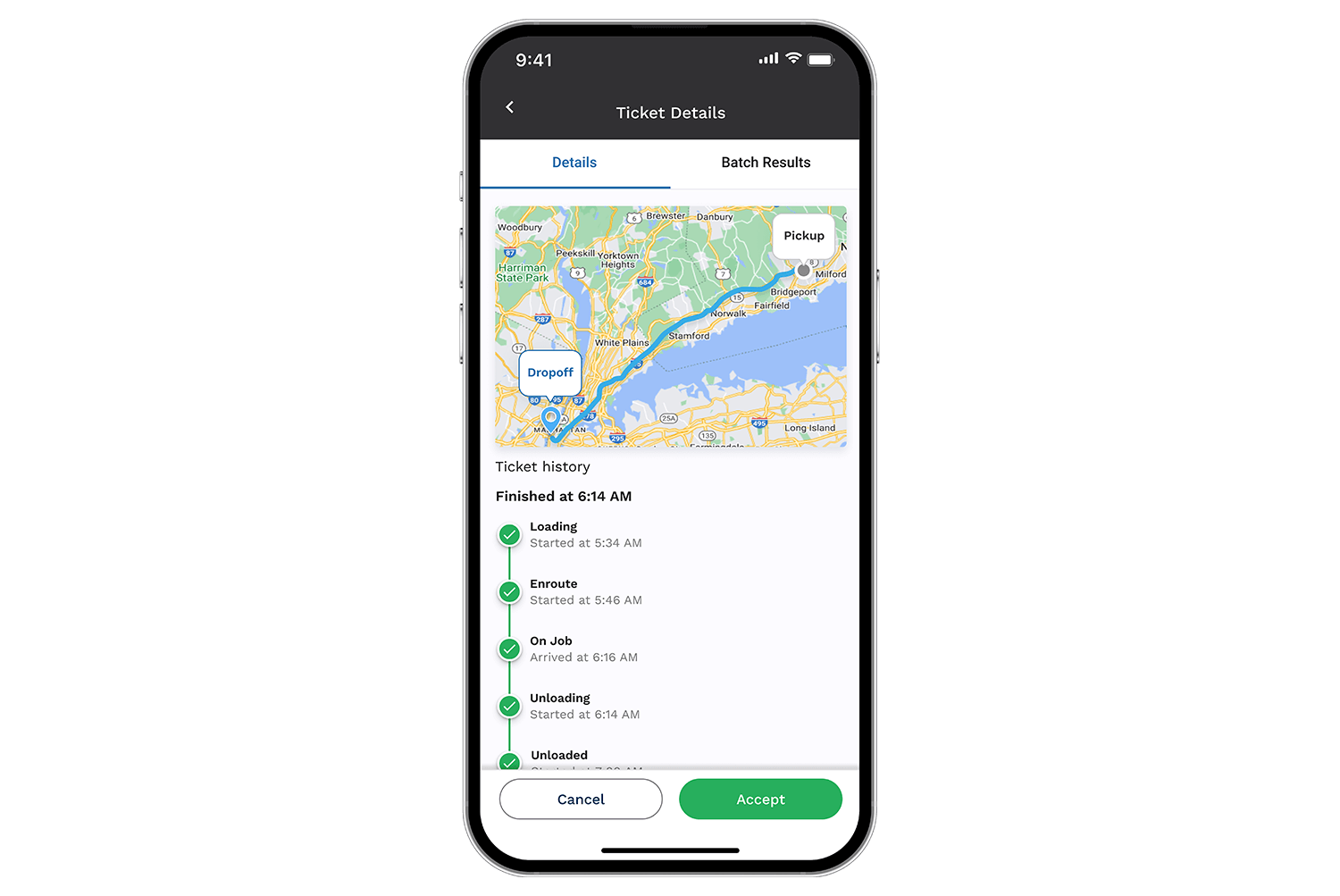

Timing and transparency are everything. That’s why we created Customer Portal. Customers request, view, and monitor their orders 24 hours a day – giving them visibility to order details and real-time delivery status while reducing the number of calls to your team. ⓘ

Your Customers Will Love It

Deliver exceptional customer service with real-time order management and status tracking in a convenient mobile app that your customers will love. Help customers keep their budgets in check by mitigating late deliveries that otherwise put their bottom lines at risk. Available for both Spanish- and English-speaking users.

The Efficiency You Want

Alleviate the strain and time your staff spend answering calls. Using Customer Portal adds a level of confidence to daily production as well as customer job site planning. Customers report reducing routine calls by as much as 30%. Quickly invite customers to download the app and begin using it in minutes.

Get Concrete Placed on Time

Optimize resource planning based on real delivery and ETA data. Construction crew managers rely on actual order data without having to pick up the phone or depend on jobsite crew. Everyone gets mobile access from anywhere – at the job site or on the road.

Extend Your Value

Drive decisions with critical data from anywhere with cloud-based dispatching

Delivering transparency into order information to Customers from a simple mobile application

Request a Demo